Flexo pre Press

Our state-of-the-art flexo pre press is fully equipped with Esko graphic workstations, powered by specialized Esko software. Manned by highly skilled designers, our flexo pre press is comprehensively integrated to seamlessly adapt your flexo artworks. We excel in adapting complex flexo designs toensure the best end results. With a strong commitment to delivering quality on time, every time, we strive to exceed your expectations.

Plate Processing

We provide advanced plate processing services while adhering to the recommended plate chemistry guidelines from our suppliers. Our Degraf 405 DW processor handles all digital image photopolymer plates and features a unique washout system. Controlled via a color touch screen, it ensures precise processing. We also offer UV coating plates, embossing blocks, and letterpress plates.

ESKO-CDI SPARK 50X80

Experience the power of our Cyrel Digital Imager (CDI) for digital imaging. Benefit from reduced cycle time, higher quality graphics, and consistent color reproduction. With digital plates, enjoy reduced dot gain, higher resolution, and better line work. Our CDI-SPARK 5080 with the latest optic model is ideal for high-quality flexo applications, offering larger plate sizes and precise imaging. Automate processes and minimize errors with the CDI, unlocking the potential of digital imaging. Esko Flexo solution continues to innovate by pushing Flexographic print Quality to new Standards. Esko CDI can expose all brands of Digital Plates used in the Flexo industry. Esko CDI has the latest Optics for fastest exposing plate.

XPS CRYSTAL 50X80 EXPOSURE

Xps Crystal’s 50×80 press was the first of its kind introduced in India by Shilp Gauvers. Our XPS Crystal system provides efficient front and back plate exposure. We also offer UV coating plates, Letterpress (Metal Back) Plates. We combine Esko CDI & XPS Crystal 50×80 for flexo plate processing, reducing manual steps and errors considerably. Hence, low wastage in plate also reduces operator’s time. The XPS Crystal delivers consistent digital flexo plates. A simultaneous & Controlled UV produces highly consistent digital flexo plates.

KODAK FLEXCEL NX 50X80

We debuted Kodak’s largest 50×80 press to the Indian market for the very first time. The Kodak Flexcel NX Digital Flexographic system represents the latest in digital Flexo plate making technology, enabling press efficiency & unprecedented print quality for flexographic printers. Kodak square spot Imaging Technology creates a predictable, repeatable, high resolution digital mark that is a pixel-to-pixel reproduction of the digital file. Screening is a feature that supports a major step forward in INK transfer efficiency by the application of micro surface texture pattern to the flexcel NX plate surface. Kodak Plate gives smoother print, higher density solids without laying down more ink. Kodak Technology has advanced dot patterns to achieve Offset type result.

Quality Control

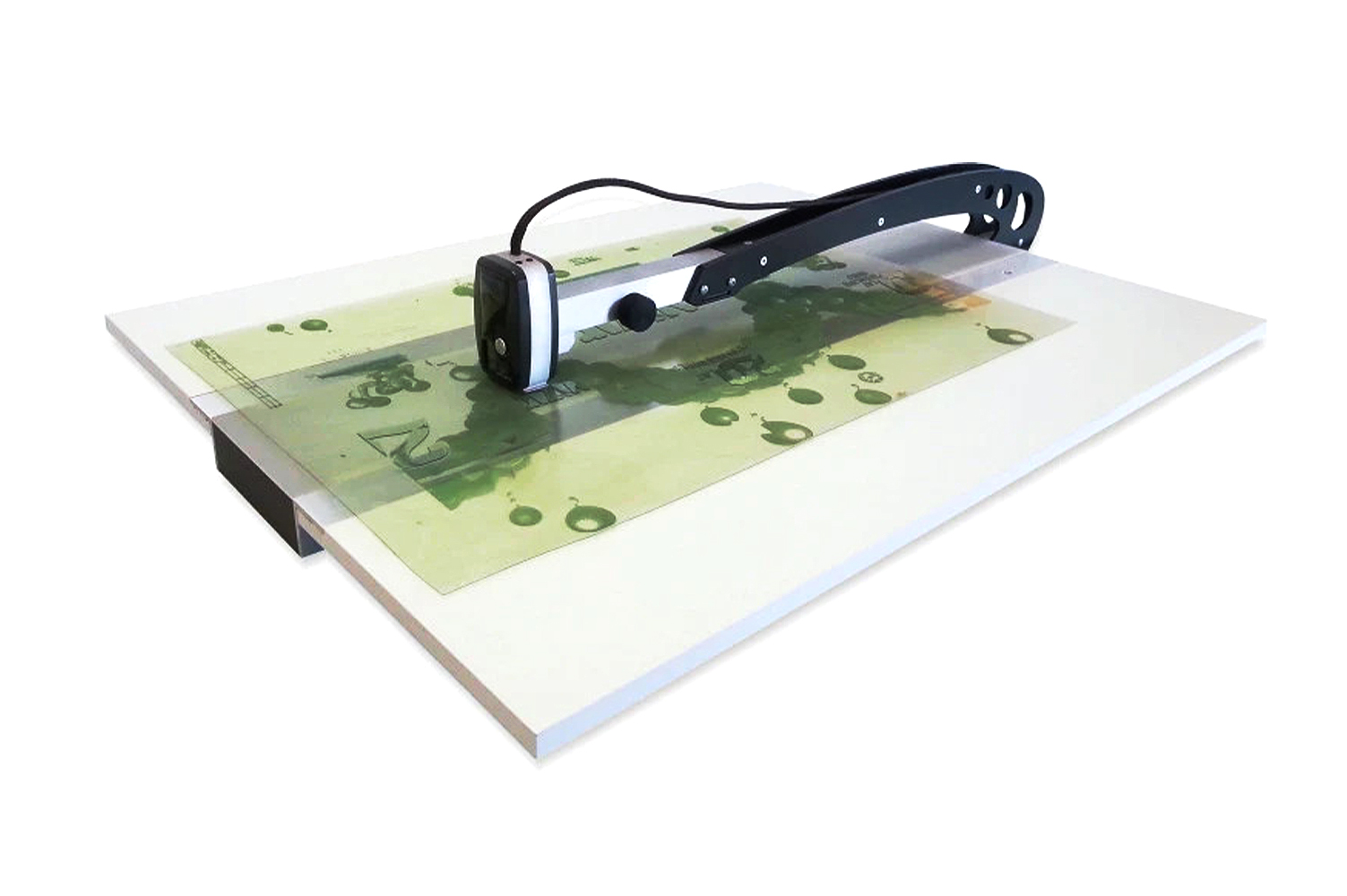

Betaflex Pro:

Mounts Betaflex Pro sensor head & Flexi-Gage 30 inches into the plate. Mask, plate and print halftone analysis as well as plate thickness and relief measurements with optional Flexi-Gage micrometer.

- Dot percentage

- Line screen

- Dot quality & parameters such as size, shape, location and screen angles

- Shore hardness of plates (Required for perfect reproduction)

- Advanced surface texturization patterns

- Hybrid Screening